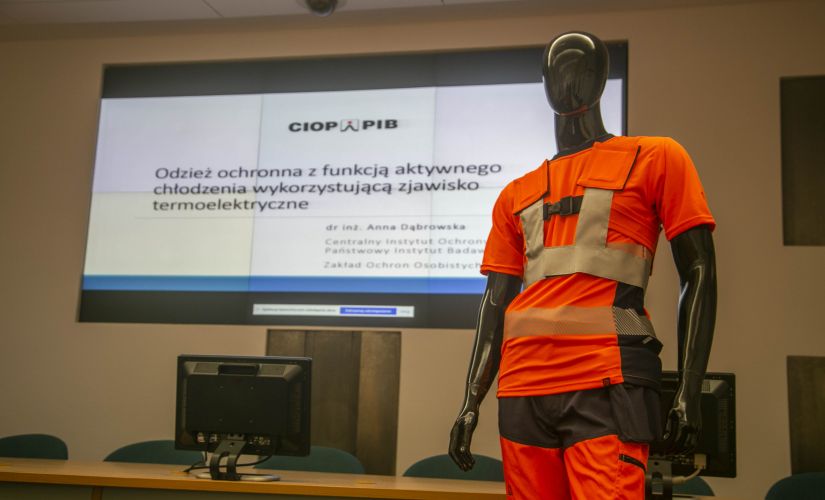

‘In developing the prototype, we took into consideration the requirements and expectations expressed by the workers participating in the test studies’ dr inż. Anna Dabrowska explained, who heads the Protective Clothing Laboratory at the Central Institute for Labour Protection - PIB in Łódź. ‘At this moment, the prototype comes in the form of a lightweight (less than 1 kg), flexible harness fitted on the body, made of materials with excellent biophysical properties. The cooling function is performed by 6 integrated flexible thermoelectric units - Peltier cells’.

Other researchers that took part in the project were dr inż. Bartosz Pękosławski and dr inż. Łukasz Starzak, Department of Microelectronics and Computer Science, TUL. The research was commissioned by CIOP-PIB as part of Phase 5 of the multiannual program ‘Improvement of occupational safety and working conditions’ with R&D funding provided by the National Research and Development Center (grant no. III.PB.09). PW Krystian Sp. z o.o. operating in Przysuchy manufactured the clothing.

Asked to explain what Peltier cells are dr inż. Łukasz Starzak said ‘Peltier cells are made of semiconducting components that rely on thermoelectric phenomena where electric current induces the flow of heat. In simple terms, they absorb heat on one end (cold) and transfer it to the other end (hot). Peltier cells are used in computers, for example, to cool down their electronic units, as well as in the mini fridges you use in your car or in your hotel room. Recent years have witness the emergence of innovative flexible Peltier modules which can be easily integrated into clothing without hindering movement’.

In order to select subcomponents that provide optimal efficiency, ease of integration, availability, and cost-effectiveness, and to design their optimal configuration, TUL researchers tested different variants of Peltier cells ‘Our chief development is an electronic, digital controller that is really easy to use and enables the user to adjust the intensity of the cooling to personal preferences’ dr inż. Łukasz Starzak stated. ‘Based on data from the temperature sensor integrated into the garment, the controller automatically adjusts the power of the Peltier modules to current conditions, e.g. ambient temperature, intensity of physical activity’.

The cooling modules are powered with a standard power bank with a USB-C plug. The innovative control algorithm designed collaboratively by the researchers from TUL and CIOP-PIB allows a 15,000 mAh battery to last for 7 hours of continuous operation at maximum power. ‘The ultra-low voltage power supply required by the cooling modules guarantees user safety even when the clothing is damp. Also, there is a self-testing procedure that disconnects the modules in case a malfunction is detected’ dr inż. Bartosz Pękosławski pointed out.

As reported by the Central Institute for Labour Protection - PIB, the protective clothing with active cooling function developed at the Institute will be now sent to KGHM Polska Miedź S.A. workers for testing.

The garment has already been successfully tested by railway workers. Its functionality can be expanded in the future to enable mobile phone control and interoperability with Internet of Things (IoT).