Granulation and surface modification of dusts after perlite expansion processes and abrasive blasting.

Surface-modified granules for stateof-the-art ecological fillers, insulation and sorption materials.

Perlite dust and dust created by blast cleaning are wastes that pollute the environment. Their storage and disposal are extremely expensive. The solution is to granulate the resulting dusts and to modify their surfaces to obtain materials with special properties, such as sorption or insulation. This technology, which is currently at the patent application stage, can be used in the construction or metallurgical industries.

Production of titanium and oxygen enriched carbon coatings via the RF PACVD method.

Surface-active, protective coatings to improve the biocompatibility of metallic implants and assist in impeding the formation of bacterial biofilm.

This technology creates coatings that combine the features of the two most commonly used materials in medicine – DLC coatings, known for their excellent mechanical properties and good biocompatibility, and titanium oxide, which has antibacterial and photocatalytic properties. Due to the presence of titanium and oxygen the coatings show surface activity that helps to slow down the formation of bacterial biofilm responsible for inflammatory reactions. This technology will be of interest to companies

involved in the production of medical implants.

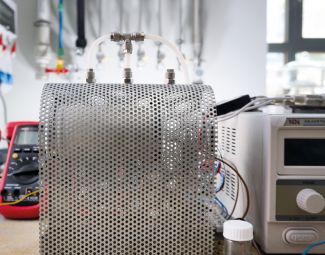

Low-pressure hydrogen storage tank based on a graphene bed.

Low-pressure, secure tank for storing hydrogen used to generate electricity.

This unique technological solution based on a graphene bed enables safe, low-pressure hydrogen storage for use in transportation equipment.

This technology will be of interest to process engineering and transportation companies

Optomechatronic device to measure material surface cleanliness after abrasive-blasting treatment.

Measuring the cleanliness of surfaces before or after the application of protective and decorative coatings to ensure uniform coverage.

One of the main prerequisites for of surface treatment is a correctly prepared surface. Classical methods of surface treatment control utilize, primarily contact measurements, which additionally limits their range of applications.

The optomechatronic method of ongoing control of surface treatment quality, developed

by a team of scientists from the Lodz University of Technology, allows for the surface fragment to be analysed continuously during the production process. This technology will be of interest to manufacturers of surface treatment control and measurement apparatus.

Wind turbine with vertical rotation axis and variable blade geometry.

IInnovative backyard wind turbine, based on Savonius turbines, consisting of two vertical blades in a form similar to the shape of a half cylinder surface, capable of generating electricity up to 1 kW.

This solution allows the curvature of the blades to be changed, making it possible to increase the power factor by up to 100% when compared with the standard Savonius turbine design. As a result of the shape change of the turbine blades the effective surface area of the striking blade is increased while the returning blade is rolled up. This produces a marked increase in efficiency.

This technology will be of interest to industries dealing with the use of renewable energy sources (especially in the prosumer area) and to wind turbine producers.

NaviFAST 6D miniature orthopaedic measuring device.

The orthopaedic miniature NaviFAST 6D device helps the surgeon to correctly position the hip implant components

and to correctly select the removable elements of modular prostheses (neck and head) during the procedure.

The technology will allow surgeons to implant a hip replacement more accurately. Until now, there was no quick and reliable method of intraoperative leg length measurement. NaviFAST 6D measures the change in length and displacement of the femur relative to the hip during the hip replacement surgery. The technology is at the stage of international patenting (USA, Europe, Japan).

The technology is intended for the orthopaedic surgery industry.

Examination of the chemical composition and structure of materials, material expertise.

This service includes testing the chemical composition and structure of materials.

Materials largely determine the durability and reliability of machinery and equipment parts. The right choice of material and processing technology is crucial for many solutions. Expertise in the performance of materials analysis of the chemical composition and structure of materials may allow the application of significantly better engineering solutions.

This service is addressed to enterprises dealing with the production or processing

of machinery and equipment parts in various industries as well as to entrepreneurs seeking new material solutions.

Optoelectronic system for movement analysis, especially the movement of people.

Motion registration and analysis is a very important element of biomechanical research. It allows for qualitative and quantitative assessment of movement parameters as well as to determine the impact of external factors.

Although similar types of systems are commercially available, the ways in which they are used may be innovative. This service may be used to record the movement of any device or any element to which markers can be attached.

The system developed by the Department of Automation, Biomechanics and Mechatronics will be of interest to athletes, biomechanics and medical engineers.

Construction, testing and analysis of the work of machines, installations and flow devices.

Design, optimization and analysis of flow machinery, equipment and installations as well as broadly understood flow tests are carried out both on the basis of experimental methods and with commercial software for numerical flow simulations.

The service offered by the Institute of Turbomachinery includes the construction of flow machines, analysis of their technical condition, optimization of existing machines, devices and installations as well as flow research and analysis.

This innovative service is addressed to entrepreneurs from the energy and chemical industries, construction offices and scientific institutions.

Laboratory strength tests, statistical and dynamic calculations and training in material strength.

This service encompasses both static and dynamic tensometric measurements of stress levels in actual structures, strength, elastooptic, fatigue and other tests.

Material strength is a basic parameter in the design and use of machines and devices. This service, offered by the Department of Strength of Materials, enables determination of basic and special strength properties of materials, which is necessary for calculations of the mechanical resistance and stability of materials, as well as of material fatigue. The service encompasses tensometric measurements, both static and dynamic, of stress levels in existing structures, strength, elastooptic, fatigue and other tests.

This service is addressed the machine and equipment construction industries. The service is supplemented by workshops.

Reverse engineering and dimensional control with a 3D scanner.

Optimization of the production process assisted by results obtained through 3D measurements.

3D measuring machines are used in many industries and are used both at the design and product development stages. GOM Inspect software is an effective solution for 3D data processing and analysis. The system is characterized by high performance and allows for reliable quality control, checking the correctness of prototypes and accomplishing measurements in the field of reverse engineering and rapid prototyping.

This service will be of interest to companies involved in the technical preparation of production, quality management and reconstruction of objects.