The European Green Deal

The problem of waste management poses a new challenge caused by its increasing accumulation. In a consumerist and highly developed Europe, this problem has been known for a long time. The threat to the environment is complex and is determined by many factors. The changing morphological composition of waste causes additional difficulties in its identification, segregation and subsequent treatment. Progressive consumption, increasing emissions, environmental degradation and irreversible changes in the depletion of natural resources have made it necessary to seek new trends and solutions. The European Green Deal provides a roadmap for a more efficient use of resources through a transition to a clean circular economy, which takes into account both financial and economic benefits, and will aim to create an environment based on the sensible and sustainable use of resources and secondary and natural raw materials.

Used tyres - an environmental bomb

Every year, millions of tonnes of rubber waste, including tyres, reach the end of their lives and become a major environmental challenge. Disposing of end-of-life tyres due to their quantity and durability is an environmental and economic problem. These tyres are a toxic, hardly biodegradable material due to the cross-linked rubber structure and the presence of stabilisers and other additives. According to the Central Statistical Office (GUS) data from 2019, about 3.8 million tonnes of used car tyres are accumulated in special landfills in Poland, and their number is still growing. Only 30% of tyres are recycled in Poland, compared to 100% in Denmark and 60% in Portugal.

A method that eats rubber

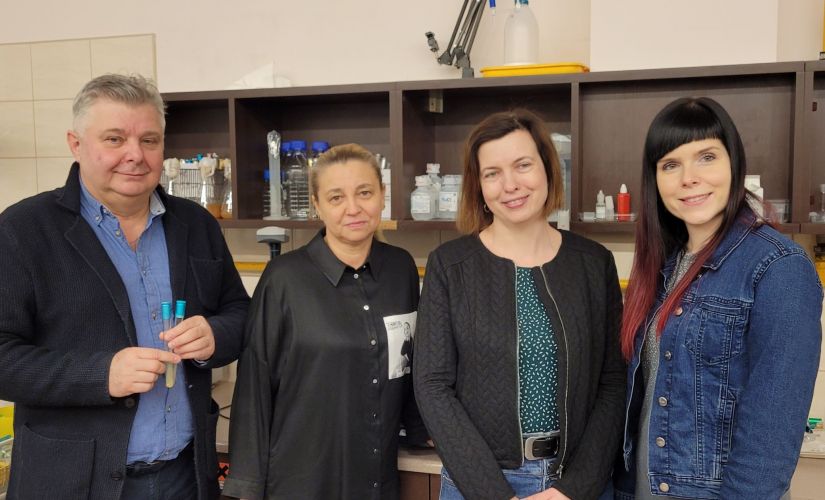

The method for utilising rubber waste has been developed by a team composed of Prof. Tomasz P. Olejnik, Prof. Katarzyna Śliżewska, Dr Eng. Marta Pietras (Faculty of Biotechnology and Food Sciences) and Dr Eng. Magdalena Kmiotek (Centre of Papermaking and Printing). The method makes it possible to utilise the technologically inferior quality of rubber in recovery and organic recycling processes (ed: the waste undergoes biological decomposition). Until now, such waste has been subjected to thermal processes and irreversibly disposed of.

The innovative method made it possible to produce barrier packaging, completely impermeable to air and completely biodegradable. The method (protected by patent P.238266) couples the activity of the Lactiplantibacillus plantarum strain (its genetic sequence protected by patent P.236113) towards the production of biocellulose. The bacteria draw energy from the rubber waste to produce bacterial cellulose. Due to its high water retention and unsatisfactory strength properties, this cellulose is not suitable for paper production. The process of producing a composite - a mixture of plant and bacterial cellulose (protected by patent P.237035) leads to an improvement in the physical and chemical properties of the resulting paper, which becomes impermeable to air.

The team does not stop at further improving the functionality of the composite and is working on reducing hydrophilicity. They are also testing ways to combine bacterial cellulose with plant cellulose.