Obtaining funding in this program is a significant achievement – FENG calls are among the most competitive in the country, and a positive substantive evaluation requires demonstrating a high level of innovativeness and real implementation potential.

1. Innovative hazardous gas analyser

The first funded project, carried out at the Faculty of Technical Physics, Information Technology and Applied Mathematics under the leadership of Prof. Tomasz Czyszanowski, is titled: "A new type of hazardous gas analyser based on photonic and optoelectronic elements."

The aim of the project is to develop a world-class product innovation – a gas analyser using large-power single-mode VarSEL lasers, a new type of surface lasers equipped with plasmonic mirrors, polarization-controlling structures, and innovative apertures. The resulting device will enable fast and extremely precise measurement of hazardous gases, both in industrial processes and environmental monitoring. The developed technology addresses global market needs for emission control and industrial process safety.

Project details

Affiliation: Faculty of Technical Physics, Information Technology and Applied Mathematics, TUL – Institute of Physics

Project leader: Prof. Tomasz Czyszanowski

Total project value: PLN 26,339,827.39

Funding for TUL: PLN 3,432,887.50

The project is implemented in a consortium with Airoptic Sp. z o.o. and the Łukasiewicz Research Network – Institute of Microelectronics and Photonics.

2. Revolution in metal hardening technology

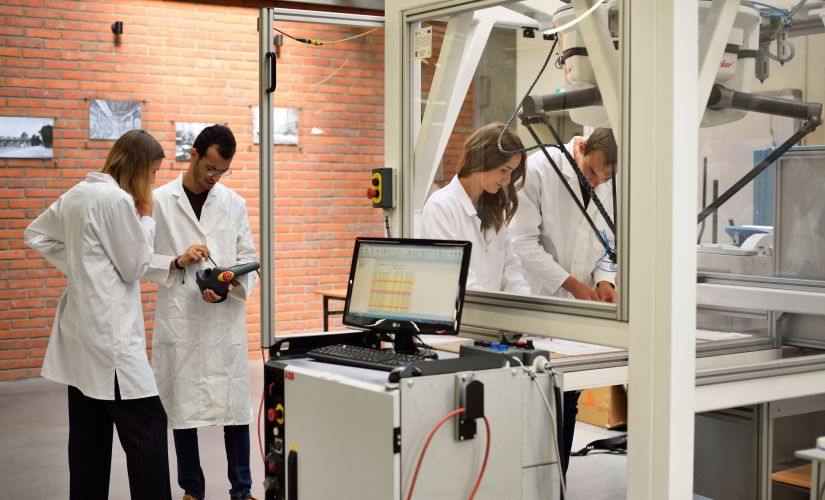

The second project, carried out at the Faculty of Mechanical Engineering under the direction of Prof. Jacek Sawicki from the Institute of Materials Engineering, is titled: "Development and construction of a prototype Free High Pressure Gas Quenching device designed for free hardening of parts."

The project plans to create a prototype of a modern device for hardening metal parts in high-pressure gas (FHPGQ) – an alternative to traditional hardening presses. The new solution will significantly reduce hardening deformation, improve the quality of components, and reduce negative environmental impacts.

The research also involves modelling and developing a digital twin of the device. Lodz University of Technology is responsible for key experimental research related to preparing a matrix defining the functional ranges of technological parameters of the device and the significance of technological process parameters and surface layers on deformation of the processed parts.

Project details

Affiliation: Faculty of Mechanical Engineering, Institute of Materials Engineering – Institute of Machine Tools and Manufacturing Technology

Project leader: Prof. Jacek Sawicki

Total project value: PLN 9,574,878.75

Funding for LUT: PLN 1,866,263.75

The project is implemented in a consortium with SECO/WARWICK S.A., a world leader in metal heat treatment technology.

Securing funding under the SMART Path is proof that Lodz University of Technology effectively links science with industrial needs, carrying out projects with a real impact on technology and economic development. Both undertakings combine the latest achievements in photonics, materials engineering, and automation, strengthening the university’s position as a key innovation centre in Poland and Europe.