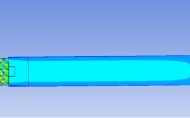

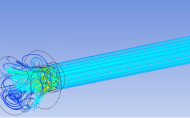

‘We relied on numerical methods to determine the most favorable oxygen supply. Once a model of the filter's shape had been made, we performed flow analyses to ensure proper heat and moisture exchanger performance was preserved’, professor Jacek Sawicki explained.

The researchers used demonstration models to conduct experiments to verify whether the engineered material performed as intended.

‘We fabricated, with 3D printing, more than a dozen models of filters made of biodegradable plastic, which were, one by one, surface modified with natural and synthetic modifiers’, professor Sawicki said. The modifications were bio-tested for bacterial and fungal growth.

The innovation aspects of the project resides not only in its reliance on 3D printing, but also in matching the shape of the filter to the currently commercially available tubes and engineering the hydrophobic and bactericidal properties of the filter material. The designers point out that the material they developed can be used not only in tracheostomy tube filtration, but can also be customized for other types of filters, e.g., those in nasal aspirators.

Patent application has been filed to protect the method of the filter material fabrication.

Beyond this year's successful presentation at the Bangkok fair, the invention was previously awarded a gold medal at the exhibition in Taiwan and a silver medal at the International Warsaw Invention Show.