Method for producing polyphenol powder extracts containing agrimoniin

Patent application P.454178 - enables the production of polyphenol powder extracts rich in agrimoniin from fragrant agrimony Agrimonia procera Wallr. The advantage of the invention is the avoidance of using toxic extraction solvents and the high efficiency of the final product. The obtained extracts can be used in the food, pharmaceutical, and cosmetic industries.

Method for producing powdered polyphenol extracts containing agrimoniin using adsorption on a polymer resin

Patent application P.454179 - creates conditions for the most complete utilization of fragrant agrimony Agrimonia procera Wallr., a raw material previously used mainly in herbal medicine. The proposed technology is an ecological and economical way to obtain concentrated agrimoniin preparations from selected morphological parts of fragrant agrimony, intended for use in the food, pharmaceutical, and cosmetic industries.

Production technology for spirit drinks flavoured with plant materials.

Flavoured spirit drinks/ flavoured vodka with an original, pleasant aroma and taste – the result of volatile alcoholic fermentation by-products and the primary and secondary aroma components of the raw materials used in the process.

The implementation of this technology developed by the Institute of Fermentation Technology and Microbiology brings many benefits. On the one hand, it increases the competitiveness of companies involved in the production of spirit drinks. On the other hand, it uses the potential of Polish agriculture to a greater extent by implementing native plant materials. The technology is a response to the recent popularity of traditional recipes and regional products. This technology will be of interest to producers of spirits, vodka factories and distilleries.

Ozonation method for liquid substances or pastes.

This technology increases the liquid – ozone interfacial contact area to significantly reduce the duration and improve the efficiency of the process compared to currently known and used procedures.

This technology developed by the Institute of General Food Chemistry involves the introduction of a liquid substance in the form of droplets with a diameter of less than 3000 microns into a chamber through which gas with a certain concentration of ozone flows. Vegetable oils introduced together with ozone serve as an innovative component with high biological activity. This technology will be of interest to pharmaceutical and cosmetics companies.

Determination of selected bioactive compounds.

A significant content of polyphenols with health-promoting effects may increase consumer interest in products.

The service offered by the Institute of Food Technology and Analysis includes the determination of polyphenols in food using high performance liquid chromatography coupled with a mass spectrometer. Due to the growing awareness of consumers about the importance of proper nutrition, demonstrating a high content of polyphenols may have an impact on increasing interest in a given product.

This service wil be of interest to companies in the food industry, especially fruit and vegetable processing industries.

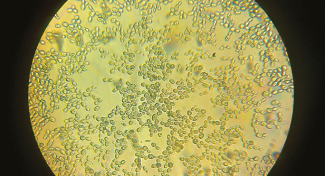

Analytical services for the fermentation industry.

Determining the qualitative composition of raw materials, semi-finished and finished products is the basis for planning and controlling the technological process of ethanol fermentation and yeast cultivation.

The offer prepared by the Institute of Fermentation Technology And Microbiology includes physicochemical analysis of raw materials, intermediates and products of the fermentation industry, testing the qualitative and quantitative composition of fermentation by-products, detection and determination of undesirable compounds, assessment of the chemical composition of distillation by-products and the analysis of biotin, yeast biomass or media used in the yeastindustry.

This service will be of interest to producers of baker’s, distiller’s, brewer’s, wine and fodder yeast as well as distilleries and companies producing vegetable oils or biofuels.

Low-waste methods for converting sugar, starch and lignocellulosic waste into bioethanol and yeast biomass.

These technologies can be used in the production of bakery, brewing, wine and feed yeast as well as for the utilization of distillers grains. They can also be used in fuel ethanol, fat and other industries.

This technology has been developed taking into account the economics of production, the desired technological features of the product and the maximum utilization of by-products. It is based on the knowledge, research facilities and rich industrial experience of the scientists from the Institute of Fermentation Technology and Microbiology.

The service will be of interest to the food, feed, distilling and environmental protection industries.

Determination of bioactive compounds and biological activity of raw materials and products of plant origin.

The service provided by the Institute of Food Technology and Analysis includes the assessment of the bioactive and health potential of food as well as of pharmaceutical raw materials and products.

Assessment of the profile and concentration of bioactive compounds, i.e. polyphenols, carotenoids, methylxanthines, proteins, peptides, etc. in food and pharmaceutical products allows for the proper design of new products that will be characterized by increased health potential. Another benefit of the service is the ability to choose and adapt a technological process so as to ensure a product with the desired properties.

This service will be of interest to the food and pharmaceutical industries.

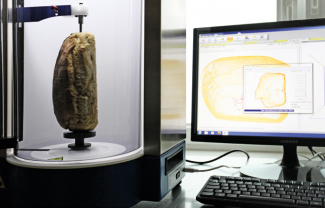

SLAC accredited laboratory evaluation of the quality and suitability of marketed sugar products.

Monitoring the compliance of sugar released onto the market with valid regulations in the Food Law and with reference to safety, legality and quality.

The sugar market now demands the assurance of high quality analytical services to guarantee the quality of sugar products, confirmed by certification.

The laboratory employs sugar quality and safety evaluation methods which are innovative on a national and European scale. It is one of only two laboratories in Poland with an official accreditation certificate from the Polish Accredition Centre.

The offer of a broad analytic scope, performed at a world-class level and in compliance with current legal regulations and the ICUMSA

Selection of storage conditions, food product composition and packaging in order to extend shelf life. Determination of shelf life, improvement of properties.

The right choice of product composition, packaging and storage conditions determines the durability and health impact of products and their competitive position on the food market.

The service offered by the Institute of Food Technology and Analysis includes modifications of the composition of a food product by adding pro-health ingredients, reducing anti-nutritional compounds and additives, developing new food products with better sensory and health-promoting properties and extended shelf life. The service also includes experimental determination of the durability of fresh and processed products.

This service will be of interest producers of fresh and processed food and feed.