He is a laureate of the NCBR Leader competition, a member of the American Society of Mechanical Engineering, the Institute of Physics, the Institution of Engineering and Technology, and the Top 500 Innovators Association. Science promoter, photography enthusiast, active in the field of academic entrepreneurship - dr inż. Grzegorz Liśkiewicz from the Faculty of Mechanical Engineering is another hero of the series "Science Talk(ie)s-the voice of young scientists".

Since high school he has been inspired by the work of Richard Feynman. He appreciates him for the fact that Feynman was always able to discover the third option – to present the problem in a different way and find an unconventional solution. It was the famous "Feynman lectures in physics" that introduced dr inż. Grzegorz Liśkiewicz to the world of science.

What are you currently working on?

My discipline is mechanical engineering. I work with scientists dealing with safety systems, signal analysis, industry 4.0 and of course mechanical engineering. In January I am launching a project that will construct a pilot stand to predict possible future compressor failures (predictive maintenance). It is as if in a fast-food restaurant a customer, who was in poor health condition, received a phone call warning him "don't eat that burger, take a month off".

The project carried out by you under the Leader program included testing and development of security devices for radial compressors. What are the effects of your work?

Let us imagine a situation where the inlet to your vacuum cleaner is blocked. The device starts to work very loudly. This phenomenon is called "pumping". For a vacuum cleaner, it means loud work. When it comes to industrial compressors with much more power, the pumping phenomenon is a huge threat to the stability of the system and the safety of its operation.

During the project, we created anti-pump protection. For this purpose, we have adapted a compressor withdrawn from use in an industrial plant (its weight is about one and a half tons). We equipped it with modern controllers that allow you to monitor its operation. This controller was used to develop security systems based on various mathematical algorithms. Thanks to the support of our Mentor - Prof. Władysław Kryłłowicz and the fantastic team (Filip Grapow, Andrzej Jaeschke, Kirill Kabalyk, Michał Kulak – in alphabetical order), two such solutions were created as part of the project. It is also the beginning of work on the next ones that we are constantly running. Together with the University of Edinburgh, we are working on a new type of security algorithms (thanks to David Garcia and Mateusz Stajuda).

Aeronautics, heavy industry, but also household appliances – compressors are the basis of many devices.

Wherever there is air movement, there is probably a compressor. Each of us has to deal with them every day. At the level of a home user, a failure of the compressor is not a big problem – it can be replaced. That is why until recently nobody even tried to apply advanced design and monitoring techniques to this type of equipment. But a visionary appeared, Sir James Dyson, who began to engage large groups of engineers to design quiet and efficient vacuum cleaners, hand blowers and hair dryers. Dyson also became famous for designing a COVID-19 respirator in 10 days in response to a call from the UK government.

And what does it look like on an industrial scale?

In heavy industry, the situation is somewhat different - every percentage of productivity is fought for. If the machine has 100 kW of power, then the improvement of its efficiency by 5% givesdr inż. Grzegorz Liśkiewicz, PŁ. about PLN 25,000 savings per year. And the cost of failure is a completely different scale. Often, without a working compressor, the entire production plant cannot function. Machines of this scale are most often made to order. The replacement will cost a lot and will take several weeks to complete. Maintaining the safety standards is therefore the long-term survival of the company.

What is your laboratory equipped with?

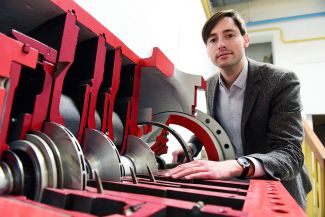

We are proud that our laboratory is growing. At present, we have three stations in the laboratory, which reflect the conditions in industrial compressors. These are our patients, whom we are trying to protect from ailments - unstable work. First we try to understand its cause and course. We measure pressure signals wherever possible. The machine is surrounded by hoses and wires, and all the data goes to a large grey box with a controller. On the other hand, we upload into the controller algorithms that control individual elements of the station (valves, engine, etc.). In this way, we "prototype" security work in industrial conditions.

During the 4th photographic biennial of the University of Silesia "Science - the world around us" the works made in the Institute of Turbomachinery were shown. Are the compressors photogenic?

It was a nice way to combine two passions: photography and compressors. I also once had the opportunity to present a photo in the "Glasgow Science Centre". In this exhibition I was most amused by the title of the exhibition given by the organizers - "Discreet Charm of the Compressor". But there is something to it! Compressor rotors can have beautiful shapes. They are like bird's wings, only metal and hidden under a heavy cast cover.

Compressors are not the only object of your research. You are also involved in the design of an algae filtering device.

Yes, we have just received information from our partner that the project has been evaluated 16/16. We cooperate with uFraction8 – a Scottish-Polish start-up developing technology for filtering biomass, including algae. The technology allows to complete in one cycle the action, which until now required a tedious, several-stage process. Together with the companies Pintech, Get Models Now, we will combine filtration modules and design flow channels allowing for their effective operation. For uFraction8, it is an opportunity to introduce a breakthrough technology, and a very interesting research challenge for us.

Is it worth engaging in interdisciplinary cooperation?

I believe that many barriers to development come from routines and habits. I used to study the aerodynamics of sails. Most of them have a triangular shape (the so-called Bermuda sails). The research of a Polish scientist - Czesław Marchaj showed that the sail would work much better if the upper 15-20% were cut. Despite such a simple solution, triangular sails still prevail on lakes. This is a simple example of how habits block progress. A similar example is in my opinion an artificial division into disciplines and sectors. That is why I see great opportunities for inspiration and scientific development in cooperation with people "from another world".

Why is it worth being a scientist?

A scientist is a lifestyle based on curiosity. It is a great adventure in which we travel into the unknown and do not stop asking questions. It is fascinating that by answering them we can change the world.