How did you develop your passion for materials engineering?

I've been interested in this field since my undergraduate studies in chemical engineering, where I first encountered materials science. I saw a lot of potential in this area, so decided to do a master's degree in biomechanics, the field which combines the areas of my interest - biology and mechanics. I wanted to take advantage of this combination by improving the quality of life in a real terms. I'm particularly interested in methods of modification on the surface of materials, because in this way many improvements in the properties of materials used for implants can be made such as a much longer service life, reducing damage to the human body.

Why did you choose such a topic of dissertation?

My goal is to create a patient-tailored trapezoidal-metacarpal implant based on incremental manufacturing technology. I was inspired by one of the projects carried out by my supervisor. It was a great decision, because this is exactly what I would like to do - combine materials engineering and biomechanics.

What groups of people will benefit from your research?

I’m keeping in mind people with disabilities , especially those with thumb problems. Such problems are exhibited by young people who often use phones and operate their thumbs in handling them. This type of activity, often many hours long, is associated with micro-trauma to tissues, which often leads to thumb dysfunction. But my task is to develop the most optimal surface treatment on biomaterials, and this could be applied to any other implant design, not just on the hand.

What is your innovation of this research?

There are such implants available today, but our goal is to optimize them. We aim to extend the life, improve mechanical and tribological properties. My goal is to match the most effective parameters of surface properties to, for example, achieve a lower coefficient of friction and wear, or extend the life of the implant, and ultimately reduce damage to the human body.

The use of 3D printing materials is also innovative. Although they are expensive, they have very good properties. The use of 3D printing will allow for the individualisation of the implant development process.

To achieve our goals, we first grasped the range of daily movements of the thumb, developed a device to simulate its operation and optimized the surface processing parameters. We used these parameters to develop the implant.

What made you choose Lodz University of Technology after studies in China?

The supervisor of my master's thesis who collaborates with TUL, presented to me the possibilities of doctoral studies in Poland and helped me choose my field of work, that's why I came.

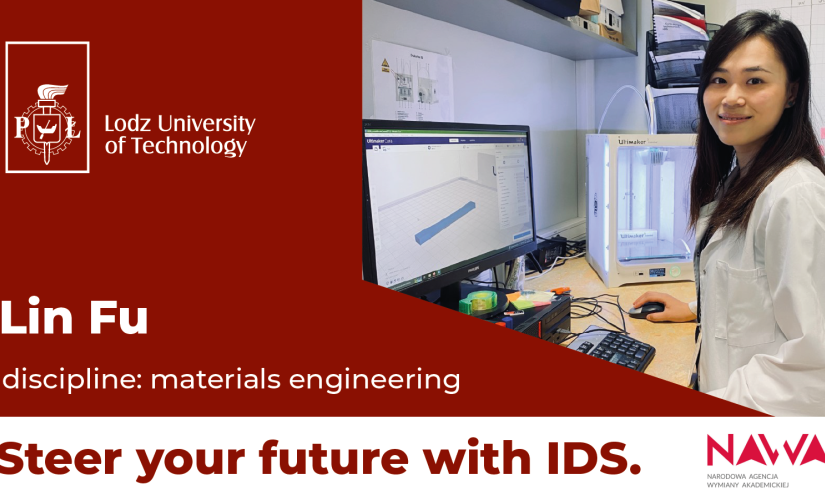

What are the benefits of studying here?

First of all, my lab at the Institute of Materials Engineering - it's great. I am impressed by the professional equipment. I also appreciate the staff who have a good knowledge of materials science and are fluent in English. Secondly, working in an international team is very valuable. My colleagues are from different countries, we talk and learn together. Finally, we have the opportunity to apply for various projects, such as trips from POWER, Erasmus, NAWA.

How do you spend your free time?

I like sports, travelling and cooking. I've been playing table tennis since I was a little girl. I usually travel in the mountains and lakes with friends, because I come from a city that is surrounded by mountains. I enjoy cooking traditional Chinese dishes, but I can also cook Polish broth.