Biodegradable material for wound dressing and hygienic purposes.

In view of the need to reduce environmental contamination, the implementation and use of biodegradable materials is now

a common trend in material technologies.

At the Institute of Material Science of Textiles and Polymer Composites, a new formation technique has been designed and developed to produce card, needled and spunbond non-woven fabrics, as well as foams and foils. Spunbond non-woven fabrics are modified to obtain strong hydrophobic features using a low-temperature plasma technique, making a skin contact layer for hygienic products.

Moreover, the non-woven materials are coated with alginate acid which provides the materials with alleviating properties and optimal pH for the human skin. Spunbond non-woven fabrics also provide an anti-bacterial finish for hospital products – hospital linen and sheets. The needled non-woven fabrics are given a hydrophile finish to obtain absorbent layers and with an anti-bacterial finish applied on the separating layer in hygienic products. This technology is suitable for applications in the production of wound dressing and hygienic materials.

Biodegradable half masks for protection of the airways and filters for industrial dust extraction.

Contamination of the air with dust is a frequent cause of respiratory conditions.

This technology, designed and developed by the Institute of Material Science of Textiles and Polymer Composites, together with partners from the Institute of Biopolymers and Chemical Fibres and the Central Institute for Labour Protection, enables the production of biodegradable filtration half masks for protection of the airways and of filters for industrial dust extraction.

The products are made of biodegradablenon-woven materials with PLA of filtration efficacy at 99% in temperatures up to 40°C, in neutral or not highly aggressive chemical environments. This technology is protected a patent application. It is suitable for applications in the production of protective clothes and filtration materials.

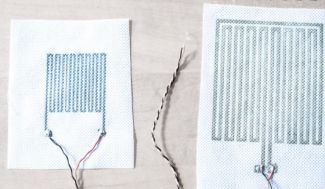

Digital printing technology for producing to produce sensory and electroconductive textiles.

One of the trends in the textile industry is the development of technologies associated with the production of textiles with electronic, textronic and electroconductive elements.

This technology, designed and developed at the Institute of Architecture of Textiles and innovative on a global scale, enables the use of digital printing techniques for industrial production of new generation textiles. This technology is intended for manufacturers of software products.

Textile charger for mobile electronic devices.

This technology provides users with constant access to electricity to maintain the operation of mobile devices, which in turn will reduce the frequency of charging a smartphones or tablets.

Research conducted by scientists at the Institute of Architecture of Textiles proved the existence of an analogy between the construction and electroconductive properties of a hybrid bunch thread and an electrical system made of solenoid with a ferromagnetic core connected in series. This made it possible to introduce a system of solenoids into fabric and knitwear as a weft and/ or warp, and to convert field energy into electromotive force induced in the copper thread as well as to alternate magnetization of the steel thread. This technology will be of interest to companies producing textronic systems and dealing with ecological solutions.

Design and production of jacquard fabrics.

The Institute of Architecture of Textiles offers complex services associated with the design and manufacturing of sample batches of jacquard fabrics.

The Laboratory is provided with a modern Jacquard loom, enabling production of preliminary pattern design samples, and the making of designed patterns.

This service will be of interest to companies in the textile and clothing industries.

Design and technological projects of clothing by CAD/CAM systems.

The Institute of Architecture of Textiles is the only unit in the country capable of preparing professional designs and technological projects for clothing based on CAD/CAM systems.

Our team of experienced engineers and designers will be happy to work with new clothing designers. The service offered by the team at the Institute encompasses the complex design of clothing by means of advanced CAD/CAM systems. This service will be of interest to companies in the textile and clothing industries.

Expertise and consultancy in the scope of woven structures and technical textile products, including those intended for composite strengthening.

The Institute of Architecture of Textiles offers complex expert services associated with the design of composite materials.

Services include expertise regarding woven structures and technical textile products, including those intended for composite reinforcement, as well as consultancy on the development of new technologies and for the design of new research projects in textiles.

This service is intended for for companies in the textile industry and for manufacturers of composite materials.

The technology for the production of duroplastic composites by the vacuum bag method and infusion.

The weight of metal structure elements used in the material industry places serious limitations in design and construction projects.

The innovative technology designed and developed at the Institute of Architecture of Textiles enables the use of the vacuum bag method and infusion to produce lightweight resistant and durable structure elements of duroplastic composites with the potential to replace metallic structure elements.

This technology is intended for producers of fiber-reinforced composite structures for the needs of construction, automotive, aviation and medical industries.

Studies of new fibre and textile product properties.

Companies in the textile industry do not always have access to specialist testing equipment or to experienced scientific personnel.

The offer of the Department encompasses tests in the scope of thermal, mechanical and rheological properties, as well as evaluation studies of the composition, colour, finish durability and formaldehyde contents in textile products. It is possible to carry out a specialist assessment of colour resistance to sweat, abrasion and washing.

This service will be of interest to manufacturers of textile products who do not have access to laboratories and test resources.

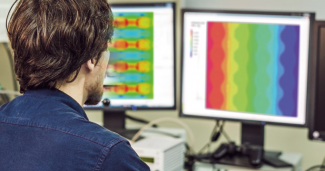

Model simulation studies of thermomechanical properties of textile composite materials.

The use of computer modelling techniques enables considerable cost reduction of material design and prototype tests. There are no other such solutions on a national level in the context of composite materials.

A system for the analysis of virtual textile composite material samples has been designed at the Department of Technical Mechanics and Computer Engineering. The analyses are carried out on the basis of a composite material project. Information provided by the simulations includes approximate coefficients of elasticity and coefficients of thermal conductivity.

This service will be of interest to companies in the textile industry, as well as to entities involved in material engineering, and the production of textile composites and textile composite preforms.

LAB-TEX accredited laboratory.

Informed consumers seek textile products with appropriate parameters. Successful protection against products incompatible with standards is based on specialist studies of textile and clothing products.

An innovative laboratory, created within the framework of the Innovative Economy Operating Programme, offers a broad range of services associated with studies and tests of electrical, mechanical and biophysical properties, as well as of the usage comfort and thermal resistance of textile products.

This service will be of interest to companies in the textile and clothing industries.